Contact our teams on +33 (0)2 41 22 99 20

BROACHING INSERTS – IPCBR/ICBFH-ISCBR

NOTES

Broaching fasteners provide strong reusable thread in nonductile material such as printed circuit boards, polycarbonates, acrylics, resins, epoxy etc. Broaching parts can also be installed into aluminum as alternative to self-clinching fasteners.

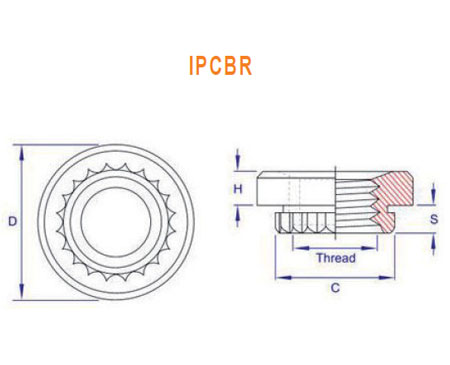

IPCBR

Thread and pitch |

S Max |

C |

D |

H |

Min Sheet

|

Hole Size

|

Min Dist to Edge |

M2.5 |

1,5 |

4,60 |

5,56 |

1,5 |

1,5 |

4,2 |

4,4 |

M3 |

1,5 |

4,60 |

5,56 |

1,5 |

1,5 |

4,2 |

4,4 |

M4 |

1,5 |

6,75 |

8,74 |

2,0 |

1,5 |

6,4 |

6,4 |

M5 |

1,5 |

7,30 |

9,53 |

3,0 |

1,5 |

6,9 |

7,1 |

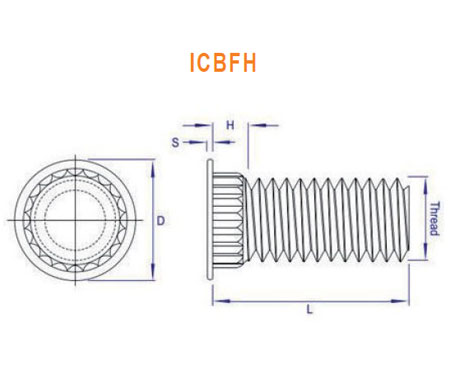

ICBFH

Thread and pitch |

Hole Size

|

Min sheet

|

D +/- 0.25 |

H Max |

S +/- 0.13 |

Min Dist to

|

Length +0.25 |

M3 |

3,0 |

1,5 |

4,58 |

2,8 |

0,51 |

3,8 |

6 – 8 – 10 – 12 – 15 – 18 |

M4 |

4,2 |

1,5 |

5,74 |

2,8 |

0,51 |

5,1 |

8 10 12 15 18 |

M5 |

5,0 |

1,5 |

6,60 |

2,8 |

0,51 |

5,3 |

6,4 |

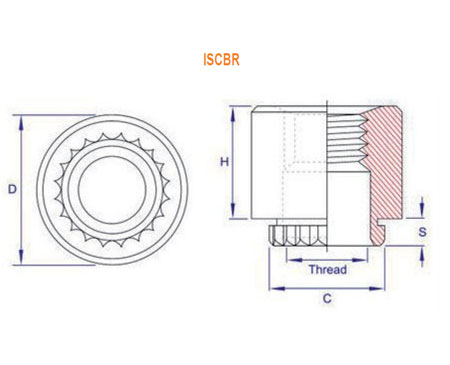

ISCBR

Thread and pitch |

S Max |

C +/- 0.08 |

D +/- 0.13 |

Min Sheet

|

Hole Size +

|

Min Dist to

|

Length+0.25 |

M2.5 / 3 |

1,5 |

4,68 |

5,56 |

1,5 |

4,2 |

4,4 |

3 – 4 – 6 – 8 – 10 – 12 – 14 – 16 |

M4 |

1,5 |

6,75 |

8,74 |

1,5 |

6,4 |

6,4 |

3 – 4 – 6 – 8 – 10 – 12 – 14 – 16 |

M5 |

1,5 |

7,30 |

9,53 |

1,5 |

6,9 |

7,1 |

3 – 4 – 6 – 8 – 10 – 12 – 14 – 16 |

Minimum thread: 3 4 6 8 totally threaded / 10 12 14 16 Thread of 9.00 +/- 0.4

MATERIALS AND PLATING

– Carbon Steel

– 300 series Stainless Steel

– Bright Zinc

– Electro plated bright Tin