Contact our teams at +33 (0)2 41 22 99 20

Lead: harmful to humans and the environment

Lead is known for its toxicity. In high doses, it can cause death in adults and children. It can affect blood pressure and kidney function, and can also cause nervous system disorders, even at low doses.

In addition to being toxic to humans, lead is also toxic to animals. It is therefore crucial to eliminate lead from commonly-used materials by replacing them with lead-free versions. On June 27, 2018, lead was added to the REACH list of substances of very high concern (SVHC).

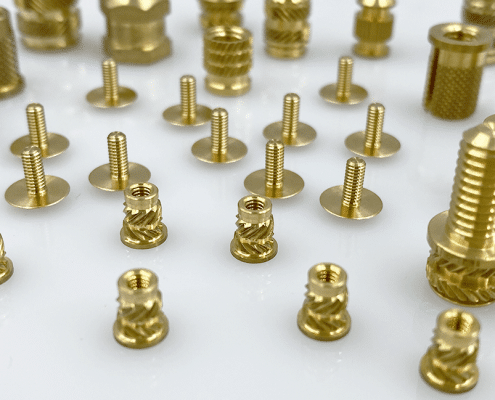

Inserco and its partner factories: expertise tailored to your needs

Steel was initially considered, but it offers several disadvantages in comparison to brass. It requires a surface treatment to protect against corrosion, which often contains heavy metals incompatible with the underlying environmental considerations. Steel is also less suitable due to its expansion coefficient for plastics processing applications. As for stainless steels, they are also composed of controversial metals (chrome and nickel). In the 20th century, a lead-free brass was developed for its polishing properties and mirror-like appearance (C69300 Silicon Brass). It is created using silicon (silicon) instead of lead.

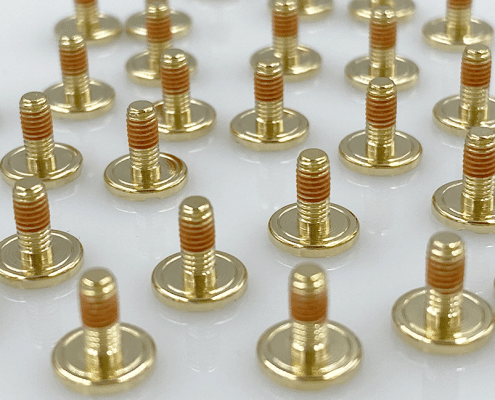

“Green brass” at Inserco: the solution for your ecological and regulatory challenges.

Whether in the electrical, automotive or luxury industry, the question of lead content in the compounds of machined materials is cause for concern, as it affects on a wide variety of fields of activity. Some sectors are more affected than others, such as the medical industry, to which specific regulations apply.

By opting for lead-free brass parts, you will save considerable time in your REACH and ROHS declarations for the monitoring of prohibited materials… So, do you have a project in mind that requires lead-free brass parts ?