Contact our teams on +33 (0)2 41 22 99 20

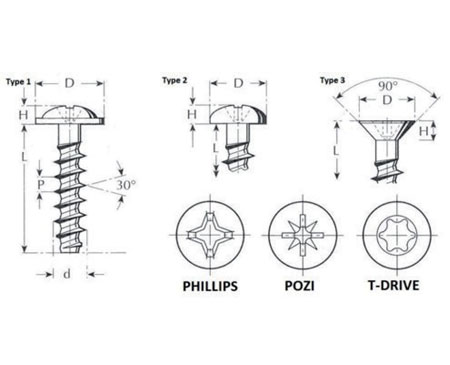

SCREWS FOR THERMOPLASTICS – SERIES IPT

APPLICATION

Screws designed to allow plastic flow during installation with a 30° thread flank angle to limit boss stress and an 8° thread pitch angle for minimum installation torque. High resistance to vibrations and plastic relaxation.

Contact us for the complete installation specifications.

SERIES IPT – Flanged button head screws

d |

H |

P |

D Phillips |

D Pozi |

D T-Drive |

2,2 |

1.60 |

0.98 |

4.40 (H1) |

4.40 (Z1) |

4.50 (T6) |

2,5 |

1.80 |

1.12 |

5.00 (H1) |

5.00 (Z1) |

5.00 (T6) |

3 |

2.10 |

1.34 |

6.00 (H1) |

6.00 (Z1) |

6.00 (T10) |

3,5 |

2.40 |

1.57 |

7.00 (H2) |

7.00 (Z2) |

7.00 (T10) |

4 |

2.50 |

1.79 |

8.00 (H2) |

8.00 (Z2) |

8.00 (T20) |

5 |

3.20 |

2.24 |

10.00 (H2) |

10.00 (Z2) |

10.00 (T20) |

6 |

4.00 |

2.69 |

12.00 (H3) |

12.00 (Z3) |

12.00 (T25) |

SERIES IPT – Button head screws

d |

H |

P |

D Phillips |

D Pozi |

D T-Drive |

2,2 |

1.50 |

0.98 |

3.90 (H1) |

3.90 (Z1) |

4.00 (T6) |

2,5 |

1.70 |

1.12 |

4.40 (H1) |

4.40 (Z1) |

4.20 (T7) |

3 |

2.00 |

1.34 |

5.30 (H1) |

5.30 (Z1) |

5.60 (T10) |

3,5 |

2.50 |

1.57 |

6.10 (H2) |

6.10 (Z2) |

6.90 (T10) |

4 |

2.70 |

1.79 |

7.00 (H2) |

7.00 (Z2) |

7.50 (T20) |

5 |

3.40 |

2.24 |

8.80 (H2) |

8.80 (Z2) |

8.20 (T20) |

6 |

4.00 |

2.69 |

10.50 (H3) |

10.50 (Z3) |

10.80 (T25) |

SERIES IPT – Countersunk head screws

d |

H |

P |

D Phillips |

D Pozi |

D T-Drive |

2,2 |

1.30 |

0.98 |

3.80 (H1) |

3.80 (Z1) |

3.80 (T6) |

2,5 |

1.75 |

1.12 |

4.70 (H1) |

4.70 (Z1) |

4.70 (T8) |

3 |

2.05 |

1.34 |

5.50 (H1) |

5.50 (Z1) |

5.50 (T8) |

3,5 |

2.80 |

1.57 |

7.30 (H2) |

7.30 (Z2) |

7.30 (T15) |

4 |

3.25 |

1.79 |

8.40 (H2) |

8.40 (Z2) |

8.40 (T20) |

5 |

3.40 |

2.24 |

9.30 (H2) |

9.30 ((Z2) |

9.30 (T20) |

6 |

3.80 |

2.69 |

11.30 (H2) |

11.30 (Z2) |

11.30 (T30) |

STANDARD LENGTHS

d |

L Length +/- 0,25 |

2,2 |

5 – 6 – 8 – 10 – 12 |

2,5 |

5 – 6 – 8 – 10 – 12 – 14 – 16 – 18 |

3 |

6 – 8 – 10 – 12 – 14 – 16 – 18 – 20 – 25 – 30 |

3,5 |

8 – 10 – 12 – 14 – 16 – 18 – 20 – 25 – 30 |

4 |

8 – 10 – 12 – 14 – 16 – 18 – 20 – 25 – 30 |

5 |

10 – 12 – 14 – 16 – 18 – 20 – 25 – 30 – 35 |

6 |

12 – 14 – 16 – 18 – 20 – 25 – 30 – 35 |

MATERIALS AND FINISH

– Steel zinc clear passivation

– Steel zinc black passivation

– Stainless

– Other materials and finishes on Steel zinc clear passivation request