MOUNTING CONSTRAINTS FOR ELECTRONICS APPLICATIONS

– Temperature variations: cause expansion and loosen fasteners

– Vibration: loosens fasteners

Internal: electro-magnetism, motors

External: vehicles, motion

– Pressure on the mounting surface of the part to fasten: expands the material and causes a loss of tension in the assembly

BENEFITS

The pre-assembled fastener has many advantages:

– Guarantees locking and resists loosening

– Facilitates assembly and disassembly (parts are pre-assembled)

– Simplifies stock management and logistics

– Eliminates non-compliance related to improper assembly or missing washers

– Let’s you combine washers without forgetting any on circuits (DC)

– Improves productivity: no need to fit washers prior to assembly

– Improves quality

We supply fasteners that meet ISO, DIN or NFE requirements and we can also produce bespoke products to your drawings.

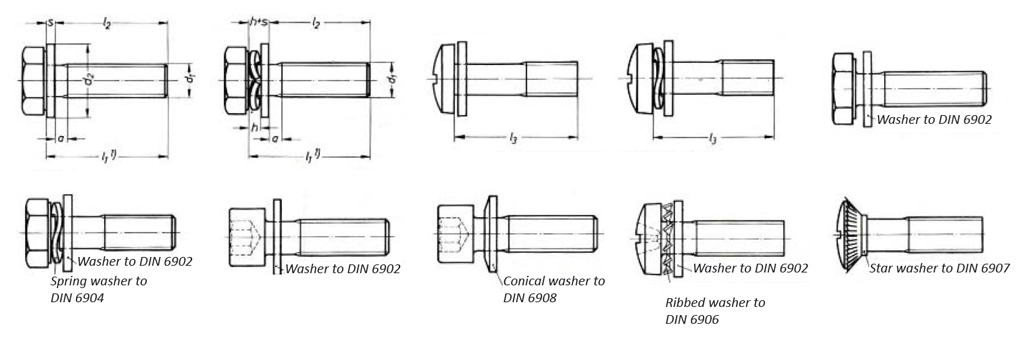

CHARACTERISTICS – SEM SCREWS SPECIALLY MADE

| Thread diameter d1 | a max. | Min. Useful screw length l2² | In excess of the lengths stated partial threading l3 | Washer dimensions | ||||||||||||||

| Hex. / hollow head screws | Slotted screws and philips/Pozi screws | Washer to DIN 6902 | Spring washer to DIN 6904 | Split lock washer to DIN 6905 | Ribbed washer to DIN 6906 | Star washer to DIN 6907 | Conical washer to DIN 6908 | |||||||||||

| Shape A | Shape B | |||||||||||||||||

| s | d2 | s | d2 | h | d2 | h | d2 | h | d2 | h | d2 | h | d2 | |||||

| M2,5 | 0,9 | 5 | 16 | 25 | 0,6 | 6,5 | 0,8 | 8 | – | – | 1,1 | 4,55 | 0,8 | 5,5 | 1,2 | 5,5 | 1 | 6 |

| M3 | 1 | 6 | 22 | 25 | 0,6 | 7 | 0,8 | 9 | 1,05 | 8 | 1,3 | 5,65 | 0,8 | 6 | 1,2 | 6 | 1,2 | 7 |

| (M3,5) | 1,2 | 7 | 25 | 25 | 0,8 | 8 | 0,8 | 11 | 1,15 | 8 | 1,3 | 6,1 | 1 | 7 | 1,5 | 7 | 1,2 | 8 |

| M4 | 1,4 | 8 | 25 | 30 | 0,8 | 9 | 1 | 12 | 1,65 | 9 | 1,4 | 6,95 | 1 | 8 | 1,5 | 8 | 1,5 | 9 |

| M5 | 1,6 | 10 | 35 | 35 | 1 | 10 | 1,6 | 15 | 1,75 | 11 | 1,7 | 8,55 | 1,2 | 9 | 1,8 | 9 | 1,8 | 11 |

| M6 | 2 | 12 | 35 | 35 | 1,6 | 12,5 | 1,6 | 18 | 2 | 12 | 2,2 | 11 | 1,4 | 11 | 2,1 | 11 | 2 | 14 |

CHARACTERISTICS – SEM SCREWS FROM STOCK

| Screw standard | Washer standard | Material | Diameter | |

| Pan head screw with flat washer | DIN 84 | DIN 6902A | CL 4,8 + ZN | M3-M5 |

| Pan head screw with spring washer | DIN 84 | DIN 127B | CL 4,8 + ZN | M3-M4 |

| Rounded head philips screw with flat washer | DIN 7985 | DIN 6902A | CL 4,8 + ZN | M3-M5 |

| Rounded head screw with ribbed washer | ISO 7048 | DIN 6797A | CL 4,8 + ZN | M3-M4 |

WIDE RANGE

SEM screws offer a wide range of assembly options. Inserco can meet all your needs by working to your drawings and/or specifications.

| Type | Standard | Material & Treatment | Diameters / Dimensions | Combinations | |

| Screw | TH, CS, CHC, CZX, … | ISO, DIN, NFE, UNC/ UNF, … | steel, zinc plated steel, stainless steel, etc. | M2,5-M6 | |

| Washer | flat, wave, conical, star, Grower, CS | DIN 6900 or non-standard | steel, zinc plated steel, stainless steel, etc. | To DIN 6900 or other | flat + wave, flat + Grower, etc. |

WHICH WASHER AND WHY?

| Flat washer | Used to spread the load for tightening No lock function |

|

| Toothed washer | The teeth have an anti-slackening function Partially damages the pressure side |

|

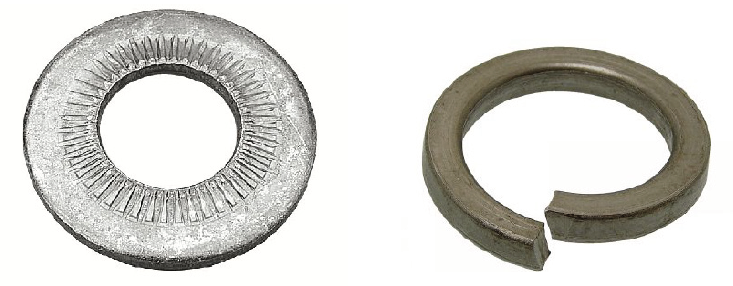

| Spring washer | Compensates for longitudinal motion due to material expansion or creeping Assembly tension is maintained |

|

| Dual-function washer | Grower (spring + one tooth) Contact (spring + teeth) |

|