Contact our teams on +33 (0)2 41 22 99 20

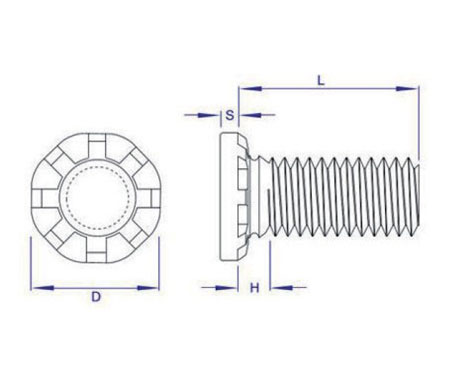

HIGH TORQUE CLINCH STUDS- IHPFH

NOTES

Maximum hardness of parent material: Steel parts – 85 HRB, Stainless Steel parts – 70 HRB. Please note that Stainless Steel parts cannot usually be successfully installed into Stainless Steel Sheet.

IHPFH

Thread and pitch |

H Max |

Min Sheet

|

Hole Size

|

S Max |

D +- 0.25 |

Min C/L

|

Torque

|

Push Out (N) |

M5 x 0.8 |

2,7 |

1,3 |

5,0 |

1,14 |

7,8 |

10,7 |

7,8 |

1496 |

M6 x 1.0 |

2,8 |

1,5 |

6,0 |

1,27 |

9,4 |

11,5 |

16,1 |

2036 |

M8 x 1.25 |

3,5 |

2,0 |

8,0 |

1,78 |

12,5 |

12,7 |

37,3 |

2787 |

M10 x 1.5 |

4,1 |

2,3 |

10,0 |

2,29 |

15,7 |

13,7 |

47,9 |

4103 |

Torque out & Push out figures are to be used as a guide only and will vary depending on panel thickness and installation method. Figures are based on installation into 1.5mm cold rolled steel for M5 & M6, and 2.3 mm cold rolled steel for M8 & m10 under test conditions.

STANDARD LENGTHS

Thread Size |

Length +/- 0.4 |

M5 |

15 – 20 – 25 – 30 – 35 – 40 – 45 – 50 |

M6 |

15 – 20 – 25 – 30 – 35 – 40 – 45 – 50 |

M8 |

15 – 20 – 25 – 30 – 35 – 40 – 45 – 50 |

M10 |

15 – 20 – 25 – 30 – 35 – 40 – 45 – 50 |

M5 |

8 – 10 – 12 – 15 – 18 – 20 – 25 – 30 – 35 |

MATERIALS AND OTHER TYPES

– Carbon Steel

– 300 series Stainless Steel

– Zinc

– Plain